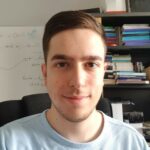

Project SOFTMANBOT: Advanced Robotic Technology for Handling Soft Materials in Manufacturing Sectors

SOFTMANBOT is an industrial-end-user driven project that will provide an innovative and holistic robotic system for the handling of flexible and deformable materials within labour-intensive production processes.

The robotic system will be composed by three main pillars including:

– a generic robotic perception system (perception of the product and the human operator),

– a multi-sensor control and planning platform (advanced control algorithms for shape and contact servoing, AI based task generalization),

– and smart dexterous grippers (smart mechanical design which will embody grasping/manipulation skills and integrate sensors – mainly tactile – for identifying precisely the contact state between the product and the gripper) able to handle soft components with high-levels of robustness and flexibility.

Context

Robots have been long employed in applications in the automotive industry, since their introduction in this sector in the middle of the last century. From that time on, robotic solutions have been adopted by many other different sectors and diverse applications in the aeronautic sector, electronics, home appliances, food industry, packaging, textile machinery etc. However, nowadays, the adoption of robotic solutions in industrial processes still remains low in a relevant number of sectors that because of the nature of their work (i.e. repetitive tasks, hazardous, etc.) could be ideally a target for this kind of solutions. This fact limits the level of automation in these industries and constrains the potential of growth of these companies, especially in determined sectors such as the textile, shoes or toy industries that need to reduce their production costs and increase the productivity because of the tough competition that they face with products coming from other international markets such as Asia (China, Bangladesh, India, etc.).

Objectives

The overall objective of the project is to develop and demonstrate an innovative and universal approach to robotic handling of flexible and deformable materials based on the integration of advanced manufacturing technologies for the automation of contact-based tasks supported by a smart robotic perception system, a multi-sensor planning and control platform and the deployment of intelligent and universally dexterous grippers able to handle soft components with high-levels of robustness and flexibility.

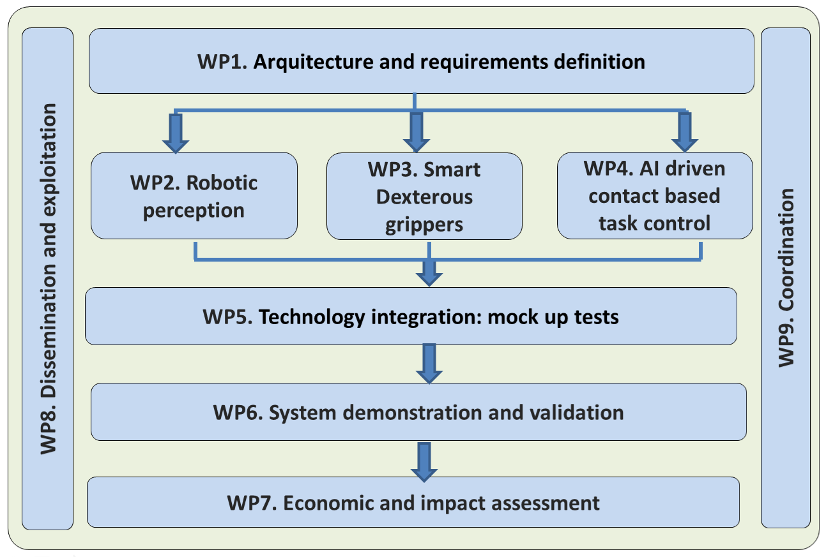

In order to complete the aim of the project, The SOFTMANBOT project will be run over 42 months with a work plan divided into 9 Work Packages.

Results

The expected results are as follows:

– A modular and interoperable architecture integrating the different systems and hardware and software components of the SOFTMANBOT robotic solution,

– A robotic perception platform for real-time parametrization and tracking of the deformation and contact state of complex flexible products integrating learning strategies,

– A multi-sensor planning and control system that taking as inputs the model of the product and the model of the human-robot interactions will implement robot skills for handling the deformation and contact of the product, establish a sequence of actions for performing the tasks, define the required outputs for interacting with the human and finally parameterize in a generic way the tasks to be done,

– Intelligent, dexterous and low-cost grippers for deformable object handling integrating embedded sensors (tactile, force, proximity, vision…) and a smart mechanical structure (embodiment of grasping/manipulation skills) able to execute handling challenging tasks with high levels of precision, fault tolerance robustness and flexibility within harshly and changing environments.

– Integration of the developed technological components and modules for the design of cost-effective and adaptive solutions for industrial applications,

– Validation of the project results in a cost-effective way under real industrial conditions through 4 pilot demonstrations in four European factories (toy, textile, footwear Execution time of demolding tasks and tyre sectors),

– An environmental (LCA), economic and social evaluation of the whole SOFTMANBOT solution, including a user acceptance assessment,

– Coordinated manner dissemination, exploitation & communication plans to maximize the project technical, social and economic impact within the demo clusters and across Europe.

Partnerships and collaborations

This project has received funding from the European Union’s Horizon 2020 research and innovation programme “Transforming European Industry” under grant agreement nº 869855.

The consortium is composed as follows:

– Sigma Clermont, University Clermont Auvergne – France,

– AIJU Technological Institute – Spain,

– INESCOP, Centro De Innovacion y Tecnologia – Spain,

– Industria Auxiliar Juema – Spain,

– Sorbonne University – France,

– Decathlon Produzione Italia – Italia,

– STAM Mastering Excellence – Italia,

– IIT, Istituto Italiano Di Tecnologia- Italia,

– Zimmer Group – Germany,

– PTH URBAN – Spain,

– Michelin – France.

More about SOFTMANBOT: http://softmanbot.eu/